In Ansbach, Germany, sporting goods company Adidas is opening the first fully operational version of its so-called Speedfactory concept, in which trainers and other sport shoes will be produced using the latest technology in computerized knitting, additive manufacturing, and robotics. A “digital twin” of the production chain, developed by Siemens, allows for testing and optimization in a virtual shop floor before actual implementation of new processes. Faster production, shorter supply chains, and more flexibility are set to make of this factory the epitome of high productivity and just-in-time manufacturing.1

In Little Rock, Arkansas, Tinyuan Garments, a Chinese company based in Suzhou, will transform an existing plant into a fully-automated T-shirt production line (for Adidas) with the technology of SoftWear Automation, a spin-off company from a research project at Georgia Tech that is financially backed by the Walmart Foundation and the Defense Advanced Research Projects Agency (DARPA). SoftWear provides its customers with robotic solutions for apparel production, shortening the distance, both temporal and geographical, between manufacturing and consumers.2

In Drachten, Netherlands, technology company Philips runs a factory in which 150 robots by Adept Technology assemble electric shaving machines, bringing production from China closer to the end customer.3 Also in the Netherlands, a container terminal of APM Terminals—a Maersk company—at the Port of Rotterdam has implemented a combination of automation technologies by Swiss company ABB with an aspiration of unprecedented efficiency in container handling.4

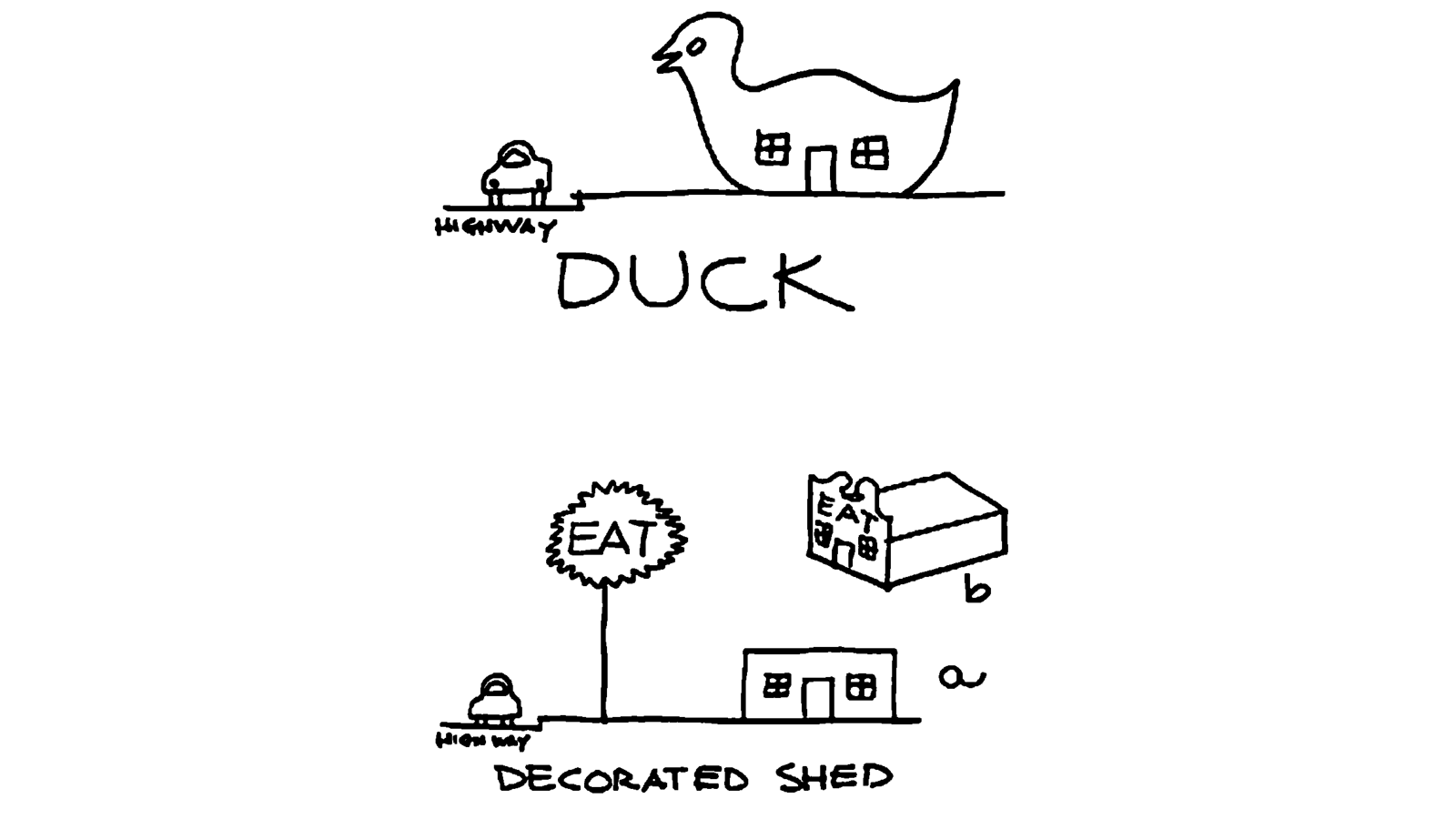

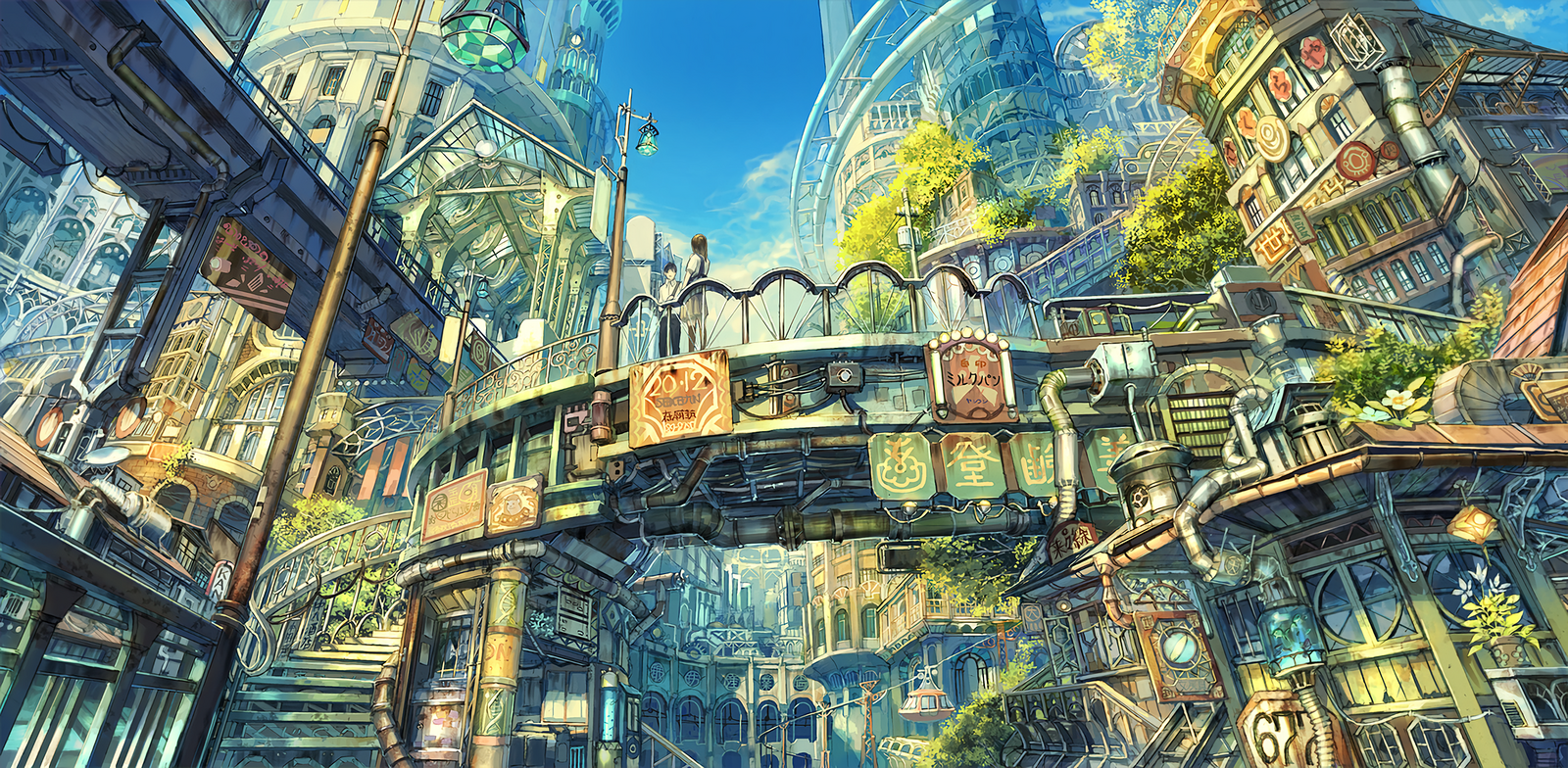

The fact that a list of similar cases could go on ad infinitum is symptomatic of emerging trend in production and logistics: the rise of automation, robotics, additive manufacturing, and diverse cyber-physical systems supported by industrial platforms provided by third parties. If for Brynjolfsson and McAffee a “platform” belongs to the realm of the internet as a “digital environment characterized by near-zero marginal cost of access, reproduction, and distribution,”5 Nick Srnicek expands this notion to that of a “basic infrastructure to mediate between different groups.”6 In this sense, industrial platforms provide hardware and software that companies need to transform conventional processes. If internet platforms have proven to have effects on urban dynamics, hardware-dependent industrial platforms—with specific spatial needs, implications, and affordances brought about by machines and sensors—are already having a deep impact on existing spatial configurations and in the materialization of typological innovations.

Despite much talk on the future of work, these emerging platform architectures—the spatial conditions and typologies resulting of converting labor-intensive industries and services to capital-intensive ones by adopting digital technologies and related platforms—are far from the architectural imagination. In the meantime, mainstream architectural scholarship and practice endorses a narrative that characterizes the discipline as one that is subject to the ongoing revolutionary technological and socioeconomic shifts, adopting innovations with little or no interest in affecting these processes, their outcomes, and ultimately, the future.

Anticipating what those platform architectures might mean for the future of the built environment and society at large is a task that is yet to be done. As the late John Urry reminded us, one method for anticipating, planning, and designing for potential, and uncertain, futures shaped by technology is to learn from the past and discern how technological innovations came into being, developed, and diffused to the point of becoming part of everyday practices.7 Looking backwards helps in understanding the processes that brought in certain outcomes and paths to technological and spatial lock-ins; examining the road to innovation, the actors at play, their interests, values, and motivations, and their consequences in the production of space are useful matter for constructing scenarios to guide future actions. An illustrative example of this with regards to how the architectural result of corporate innovations and revolutionary industrial platforms alter conventional architectural practices is the story behind the emergence and diffusion of the typology that first embodied modern industry: the daylight factory.

A Modern Platform

Before the arrival of the factory, shoe manufacturing in Lynn, Massachussetts, was based on the so-called “putting-out” system. Introduced by John Adam Dagyr in the 1750s, it was a first attempt to update shoe manufacturing from the mode of craftsmen working for a local market to a system of production capable of supplying an expanding market in one of the most densely populated areas in the country. The production of individual piece works was done in a decentralized manner by a network of craftsmen working for a boss, or shoe manufacturer.8 The work was carried out in three different types, units of space, depending on their activity: binding was done at home by women, bottoming was done by groups of men in a building known as the “ten-footer,”9 and the resulting products were inspected, and if necessary, finished and cut in a central shop, owned by the boss, where materials for a new cycle of production were also distributed among the craftsmen.10 In the context of currency and credit problems prior to Civil War, the need for entrepreneurs to preserve and concentrate capital meant that workers were generally not paid cash wages, but tickets to purchase goods in stores owned by the shoe manufacturer.11

The railroad and the opening to new and remote markets it afforded imposed a spatial order in which business and manufacturing became centralized around the valuable lands surrounding the station. Vertical factories emerged as a result of this consolidation of capital and increased competition for location.12 The introduction of the factory radically changed industrial systems of production, finally allowing work to be centralized under the scrutiny of a boss. More capital and large spaces of production also made possible the introduction of the latest machinery, such as the McKay sole-sewing machine in 1858 and Jan Ernest Matzeliger’s shoe lasting machine from Lynn in 1885.

Mechanization made production take on a different dynamic: instead of all tasks being performed by a single worker using a variety of tools, the task of making a shoe—cutting, binding, lasting, and soling—were divided into discrete steps and further subdivided in single operations that could each be performed specialized machines operated by a single person. The development of the shoe machinery industry reached an unprecedented dimension with the consolidation of forty-one smaller shoe machine-making companies into a factory complex in the city of Beverly, Lynn’s neighbor to the north, and the establishment of the United Shoe Machinery Corporation (USMC) in 1899.13 Most importantly, the USMC introduced what was at the time an original business model, the “leasing system,” which allowed manufacturers to adopt an industrial platform of modern machinery and services via a subscription fee, thus minimizing the entry cost to new machinery for customers while at the same time offering a quality of customer service and maintenance that only a large manufacturer could otherwise provide.14 By 1911, the USMC would hold control on ninety-eight percent of the shoe machinery business in the country.

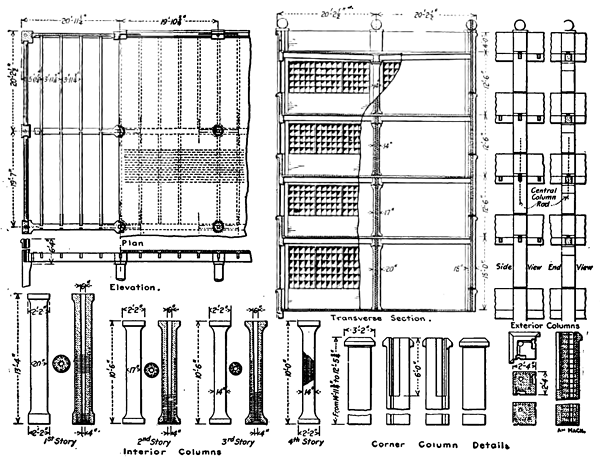

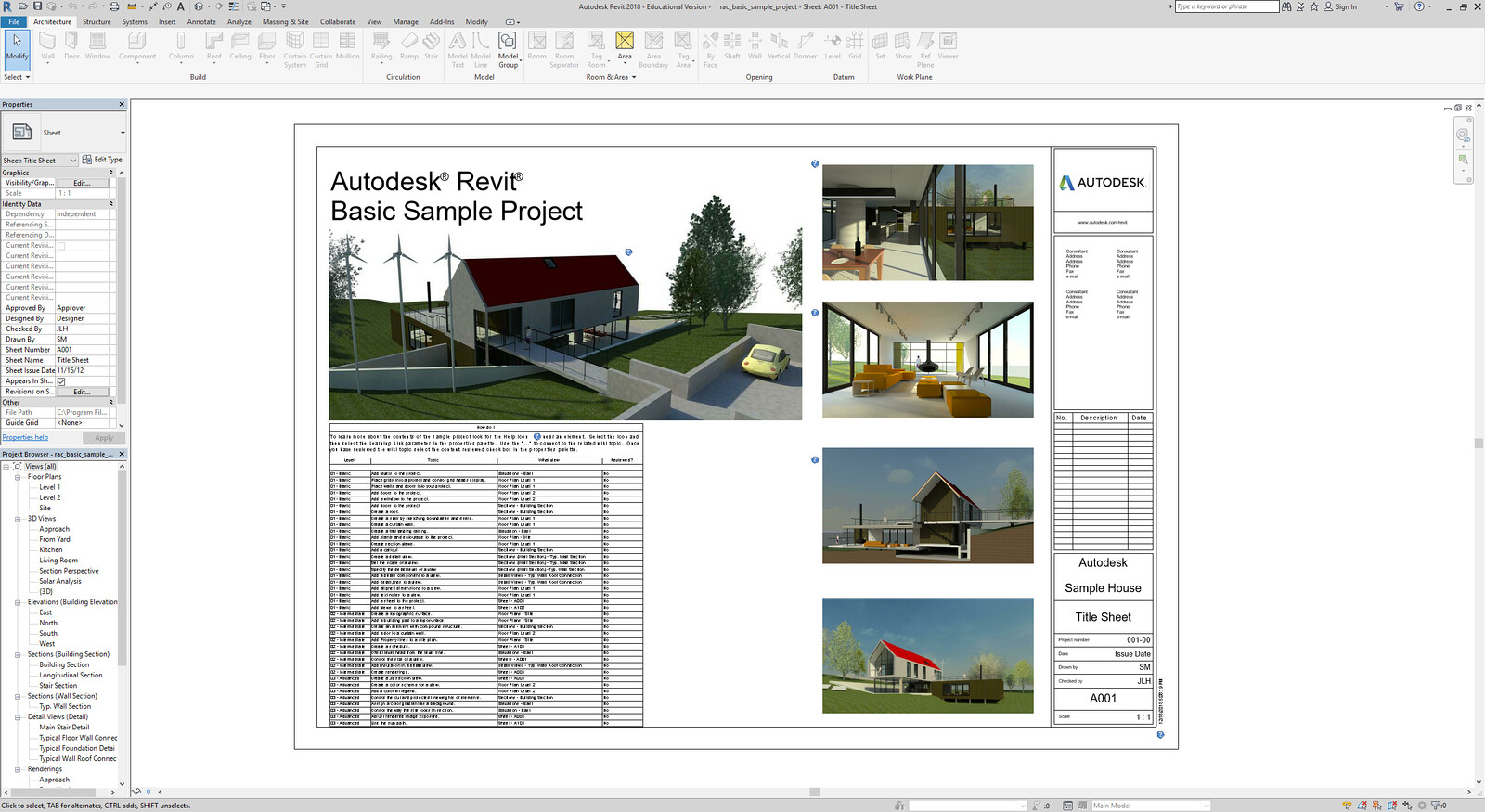

Details of the “Ransome Unit System” from Ernest L. Ransome and Alex Saurbrey’s Reinforced Concrete Buildings, 1912.

The USMC and the Former Tradition

At the time of the boom of American shoe making industry, factories and industrial constructions followed what Reyner Banham called the “former tradition” as variations on the New England mill type: multi-story, compact in plan, long and narrow constructions, whose structure consisted on an internal timber frame and external brick walls pierced with segmented arched windows.15 With the boom of textile industry in New England, such multi-story mills had sprung up along the region’s river banks. What originally drove the New England mill’s typological development was the type of power transmission systems in use at the time, the competition for access to water they demanded, and the need for natural light. The introduction of electricity and the arrival of the railway altered the logic for the location of industry, but competition for the best location—now guided by having access to railways—and the paternalist preoccupation for better working spaces—aimed at gaining employees’ loyalty and avoiding labor conflict—continued and added to the centralization of shoe manufacturing. Yet the old building type kept making sense. As a result, in Lynn and elsewhere in New England, multi-story brick factories following the mill model grew around railroad stations.

However, in those years it was clear that a revolution in the use of materials and form was crystallizing, which the new USMC factory would epitomize as the emergence of a “concrete Atlantis.”16 The building for the USMC was built between 1903–1906 by Ernest L. Ransome. Ransome was born in England in 1852, and in practice trained as an engineer by working in the family businesses, which included the production of artificial stone and cement. In America, Ransome started to develop and file patents for a system of construction based on reinforced monolithic concrete structures capable of resisting both fire and earthquakes. After a series of built works in California, his name would shadow other American concrete pioneers when the structure of one of his buildings, the curiously named Pacific Coast Borax building of 1897—considered the first reinforced concrete factory on the East Coast—survived a great fire in 1902. Shortly after that, Ransome realized that solid, non-load-bearing walls had no purpose anymore in modern construction, and that they could be just made of glass; natural light would increase safety, quality control, and working conditions.17 The construction of the second phase of the Pacific Coast Borax in 1903 and the factory for the USMC were the culmination of Ransome’s work designing multi-story well-lit concrete frame structures.

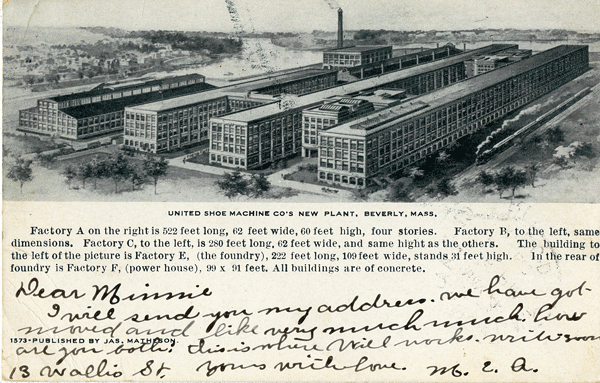

Postcard depicting Ernest L. Ransome, United Shoe Machinery Corporation plant, Berverly, Massachussetts, 1903–1906.

Its colossal scale made the USMC plant, known colloquially in Berverly as “the Shoe,” Ransome’s most impressive work. The plant was formed of three parallel sixty-two-feet wide, four-story wings running north-south, eighty feet apart from each other, joined by two rows of connecting volumes of equal height. The structural frame of the wings was formed by twenty-by-twenty feet bays, making each building three aisles wide. The two wings on the east had the same length (522 ft), and the westernmost was shorter almost by half (280 ft). The linking block at the south connected all three wings, while the one at the north connected just the longest two, enclosing a giant courtyard.

Ransome’s concrete system for USMC, reinforced with twisted iron bars, used a combination of on-site poured and precast elements, giving the building a modular serenity and rational simplicity. The elevation of the wings were unornamented concrete frames with large windows. In spite of the utilitarian character of the facade, Ransome made some concessions to classicism by making of the first floor a solid base with arched windows, and had simple string courses mark the transition from base to body, body to frieze, and frieze to cornice.18 The USMC plant would become the “canonical form”19 of what Ransome himself considered a “modern type”20 of industrial architecture: the daylight factory.

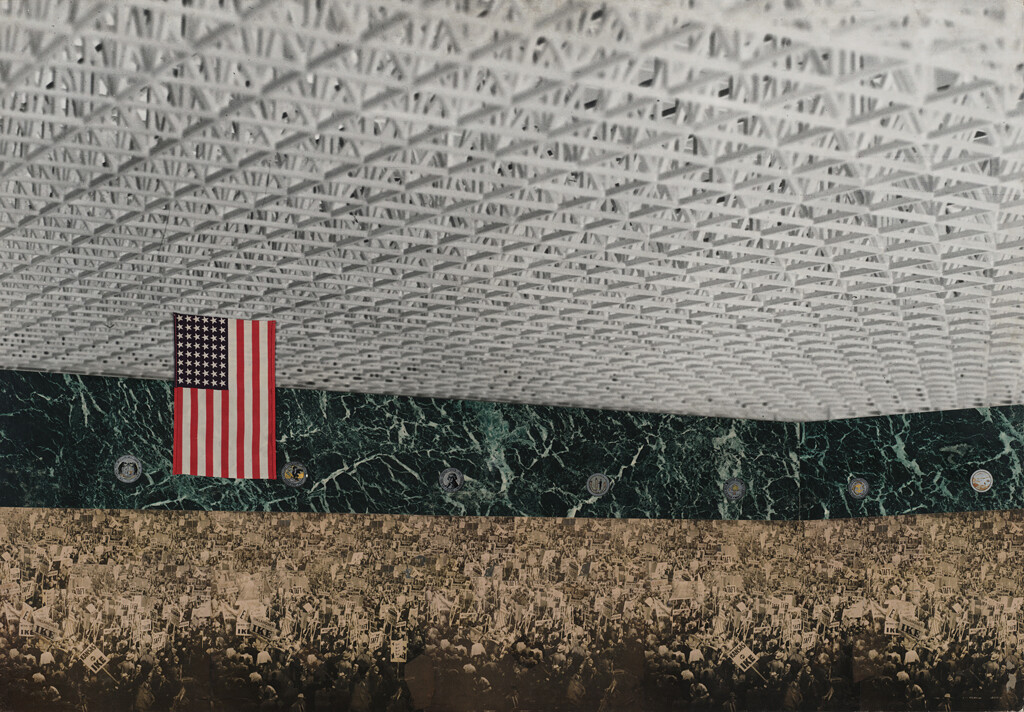

When it first opened in 1905, clients and visitors to the UMSC not only got acquainted with the most up-to-date knowledge about and machinery for the production of shoes, but also with a building that in its massive scale, structural and land-use efficiency, and light-filled flexible spaces was ready to serve the needs of modern industry. Upon his visit to the building in 1905, Czech shoemaker Tomáš Baťa praised its “monumentality,” large windows, and well-lit wide spaces that allowed to do “any kind of work there.”21 His company would go on to reproduce and circulate the daylight factory type in factories built around the world.22 Some years later, when in 1913 members of the Benscheidt family, owners of the Fagus shoe-last company, would commission Walter Gropius to design their new factory in Alfeld, they would show images of the USMC factory from their visit in 1910.23 His radical design for the factory, with its purity of form and fully glazed facades, “stands,” in Banham’s words, “debatably, at the beginning of the ‘Americanization’ of European modern architecture.”24

Alternative Sources

The influence of the USMC factory in the production of architecture went far beyond the appropriation of its design by modern European architects or the technicalities of reinforced concrete construction, as the company itself would disseminate its views on architecture. In 1916, USMC published the Handbook of Shoe Factory Engineering, a forty-two-page booklet that presented clear and concrete design guidelines for a modern shoe factory based on the company’s experience with the “building problem” that its clients faced when introducing USMC’s modern machinery.25 Developed and disseminated by the Department of Agencies—the internal department in charge of the sales branches—the booklet established a connection between economy and efficiency in manufacturing, the requirements of its machines, and the spatial features of the factory. The authors argued that in times of increasing demand for mass-produced shoes, manufacturing was hampered by old buildings that had reached their “logical limit,” unable to meet the requirements of a modern industry with regard to “light, heat, power, equipment, and interior organization.”26

Should the shoe manufacturer follow the design guidelines presented in the booklet when constructing a new factory, USMC promised the building would be “ideal in construction and arrangement.”27 In spite of its higher cost, concrete was recommended as a construction material as opposed to wood for its fire resistance and low maintenance requirements, and subsequently lower insurance costs. Such an “ideal shoe factory” had to be rectangular in plan—“years of experience have proved that a rectangular shaped building … works out to the best advantage”—preferably fifty feet wide, divided in two aisles, and with a variable, but maximum length of one thousand feet. The length, and therefore the final square footage, depended on the output demanded and number or standard USMC machines needed. The factory was to be three-stories high plus a basement, rationally dividing and stacking the manufacturing process with materials flowing from top to bottom on elevators. Service spaces and circulation elements were to be pushed out of the main volume and attached onto the façade in a rhythmic fashion, allowing the rectangular open plan to be used in its entirety with optimal degrees of flexibility.

Flexibility to quickly rearrange production lines each season was not only to be achieved by an open grid plan, but also by the adoption of new power sources and mobile furniture. The addition of new and more powerful electric motors were more cost-efficient than upgrading old, steam power-based systems when needed for increased output. Most importantly, whereas in steam powered factories machines had to be linked to fixed drive belts that mechanically, and unefficiently, distributed power from the main engine, the electrical powered machines were not bound to a permanent location. Furthermore, changes to come in the manufacturing process could be more easily incorporated with the use of standardized metal equipment and all sort of mobile racks and shelves.

Finally, light, ventilation, and a comfortable working environment were of paramount importance for an ideal factory. In the opinion of the USMC engineers, a fifty-foot wide building was perfect as it both gave enough space for the storage of shoes awaiting operation and guaranteed that sufficient natural light would reach the central section of the plan. Adequate light and ventilation was also conditioned by a preferred floor-to-ceiling height of eleven feet and six inches, and as “there is no one who will argue that you can have too much light,” the building envelope was to be fully glazed.28 In addition to those environmental concerns, the handbook strongly recommended the inclusion of facilities in the factory aimed at the “employee’s welfare” such as restrooms, an infirmary, canteen, and recreation rooms. For the USMC, “it would seem a mistake to leave this feature without consideration.”29

Publications such as the The Handbook of Shoe Factory Engineering reveal corporate practice, and ultimately corporate interest, as an alternative means for the transmission of architectural knowledge. In the end, the USMC advocated for modern industrial buildings—the daylight factory—because its adoption would allow for the company’s economic reproduction. The leasing system used by the USMC facilitated the adoption of new machines by shoe manufacturers, yet old industrial architectures were a limiting factor for their adoption. With the Handbook, the UMSC invited manufacturers to embrace a new spatial, productive, and energetic scheme of industry, embodied in a particular architectural typology.

Researching Platform Architectures

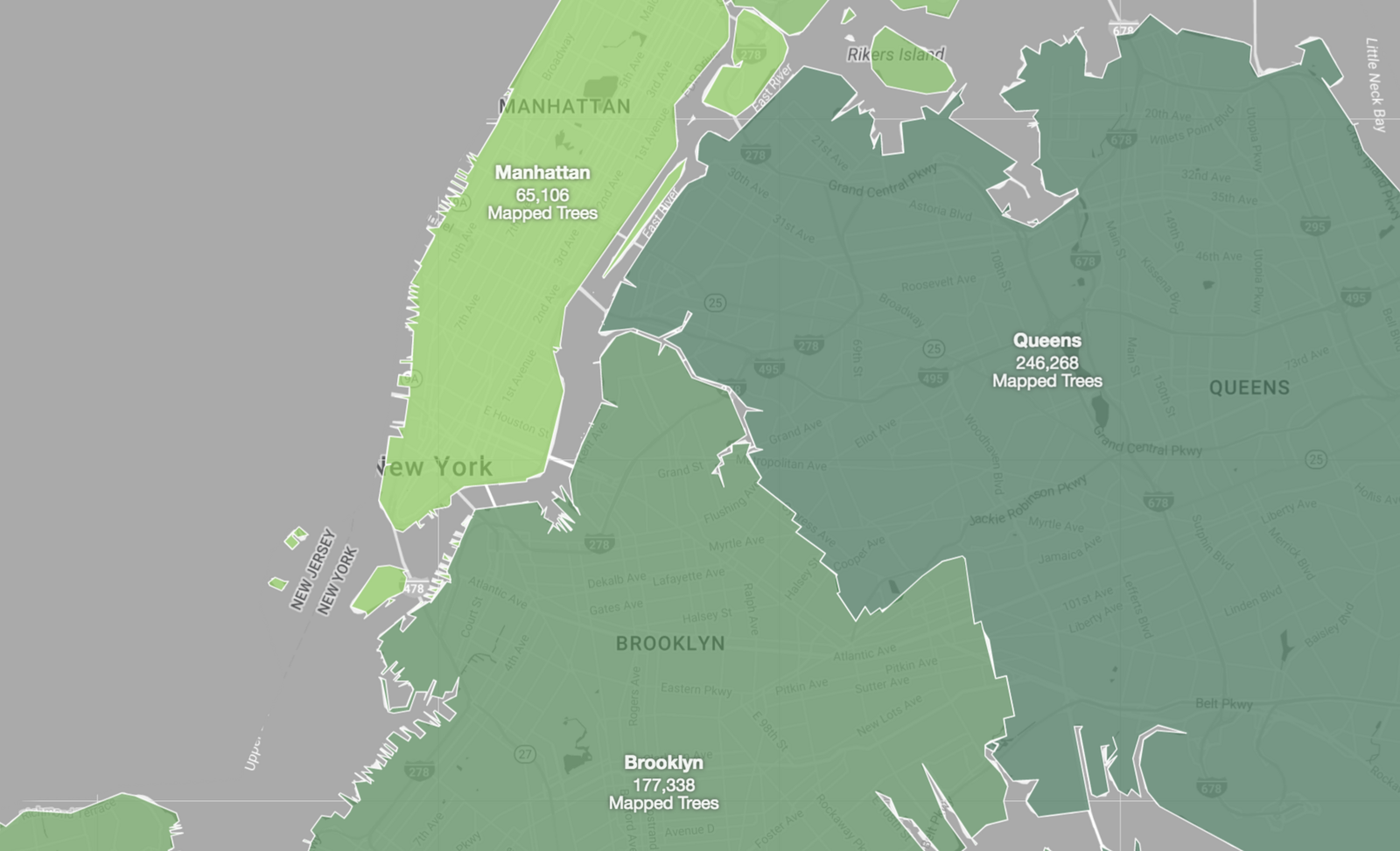

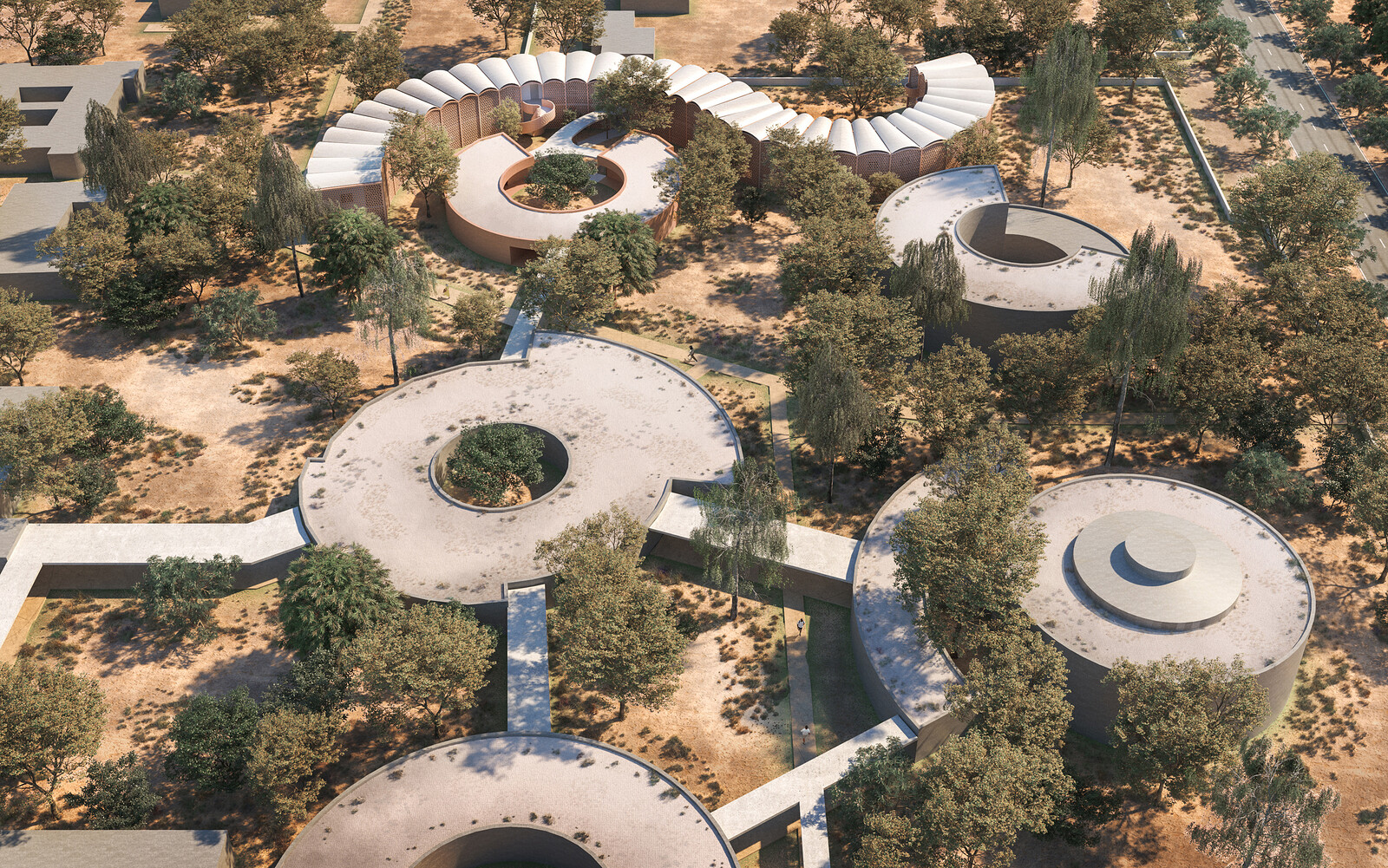

In contrast to common views in architectural and urban history and theory, research into platform architectures could show that a core variable in the production of architecture throughout history has been the initiatives and ideas of industrial entrepreneurs. This would shift how we view the meaning of architectural design and urbanism in relation to societal and economic developments, and also the way corporate actors work to continuously shape the built environment. Today, the ideas and technologies behind the daylight factory have given way to the so-called lights-out factories: automated workscapes of non-human labor. Meanwhile, platforms are reaching more expansive, diffuse realms within the built environment, such as in the case of smart city technologies. Platforms compete for monopoly. They lock architectures, landscapes, and those residing in them into cyber-physical ecosystems prone to becoming either obsolete or hackable.30

The city and its architectures are being positioned as a test bed for new logics of production and management defined by platforms. Without a thorough research on the past and emerging—often anonymous—trends in the design of platform architectures, developing new methods to unmask the opacity of corporate developments, and understanding how these could produce and reproduce forms of inequality, segregation, and risk, the architecture discipline cannot fully understand the impact of economic decisions and the organization of industrial processes on the organization of spaces and society. Such disregard ultimately leads to a missed opportunity to use design in anticipating, and maybe even alleviating, the effects of new industrial revolutions; not to mention intervene and maximize its benefits for society at large.

“Adidas and Siemens set to collaborate in the digital production of sporting goods,” Siemens Global, (April 24, 2017), ➝.

“WTIN: Rethinking the Textile Supply Chain,” Softwear Automation Press & Events (August 18, 2017), ➝.

Frank Gersdorf and Heiko Jessayan, “De mens ontwerpt, de robot zet in elkaar,” Het Financiele Dagblad (October 30, 2014), ➝.

Víctor Muñoz Sanz, “Welcome to Futureland. Automation Takes Command in the Port of Rotterdam,” Volume 49 (September 2016), 33–38.

Andrew McAfee and Erik Brynjolfsson, Machine, Platform, Crowd: Harnessing Our Digital Future (New York: W. W. Norton & Company, 2017), 149.

Nick Srnicek, Platform Capitalism (Cambridge: Polity Press, 2016), 43.

John Urry, What is the Future? (Cambridge: Polity Press, 2016).

William H. Mulligan, Jr, “Mechanization and Work in the American Shoe Industry: Lynn, Massachusetts, 1852-1883,” The Journal of Economic History 41, 1 (1981), 59.

Ross Thomson, The Path to Mechanized Shoe Production in the United States (Chapel Hill, NC: UNC Press Books, 1989).

Robert Enoch Buck, “Railroads and Capital: Money, Credit, and the Industrialization of Shoemaking,” American Journal of Economics and Sociology 57, 4 (1998) 513.

Ibid.

Sidney Kaplan. 1955. “Jan Earnst Matzeliger and the Making of the Shoe,” The Journal of Negro History 40, 1 (1955), 840.

Richard Roe, “The United Shoe Machinery Company,” Journal of Political Economy 21, 10 (1913), 938–953; Richard Roe, “The United Shoe Machinery Company,” Journal of Political Economy 22, 1 (1914), 43–63.

Reyner Banham, A Concrete Atlantis: U.S. Industrial Building and European Modern Architecture, 1900-1925 (Cambridge, MA: MIT Press, 1986).

Ibid.

Gwendolyn Wright, USA. Modern Architectures in History (London: Reaktion, 2008).

Ibid., Banham.

Ibid.

As quoted in Ibid., Wright, 53.

As quoted in: Jiří Svoboda, Jiří Voženílek: Architekt ve Zlíně - Architect in Zlín (Brno: Brno University of Technology, National Heritage Institute, 2011), 19.

Víctor Muñoz Sanz, Networked Utopia. Architecture and Urbanism in the Bata Shoe Company satellite cities, 1930 to the present (Doctoral Dissertation: Universidad Politécnica de Madrid, 2016).

Andrew Tenner, “Lasting Impressions,” Harvard Magazine, (September 1, 2000), ➝; Ibid., Wright.

Ibid., Banham, 68.

Department of Agencies of the United Shoe Machinery Company, Handbook of Shoe Factory Engineering (Boston, MA: Department of Agencies of the United Shoe Machinery Company, 1916), ➝.

Ibid., 5.

Ibid., 6.

Ibid., 11.

Ibid., 12–13.

Víctor Muñoz Sanz, “Captives in Futureland,” Volume 51 (2017).

Positions is an independent initiative of e-flux Architecture.

Positions is an initiative of e-flux Architecture.

(2014).jpg,1600)

,-2003,-srgb.jpg,1600)